- Converting Tracepaper 2.0 Integration

After choosing the server with the correct technical characteristics we will install the necessary software from the OS. An MSSQL server will then be installed to manage incoming data from the plants. Finally, a SCADA software will be installed able to communicate with the various electronic devices within the individual lines.

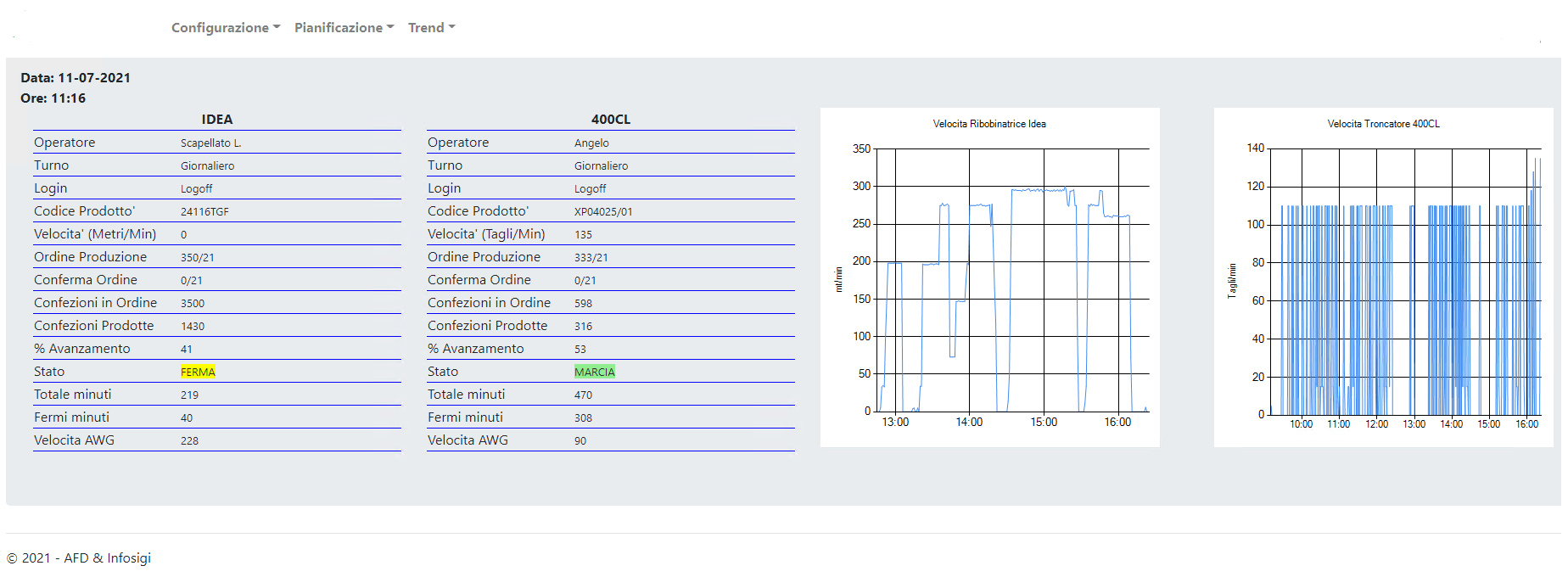

The data will be collected by the Scada in real time and stored in MSSQL tables and will be made available to users through cards that will be displayed on tablets and HMI pages.

The various development programs for PLC, axis control, operator panels of the various lines will then be installed. In this way it will be possible, by activating secure and reliable VPNs, to access remote assistance even from remote locations.

─ SAMPLE BOARDS

Track, Record, Collect, Display

─ 1

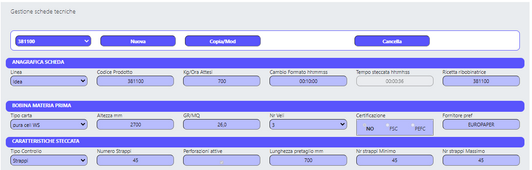

Define standard

Define the expected result for each product

─ 2

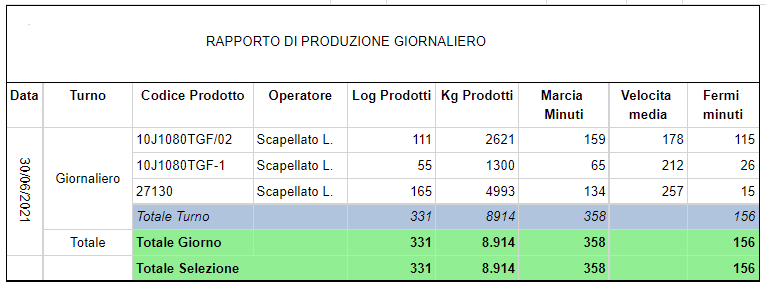

Collect data

Record information on line trends

─ 3

Track consumption

Collect raw material consumption and production data.

─ 4

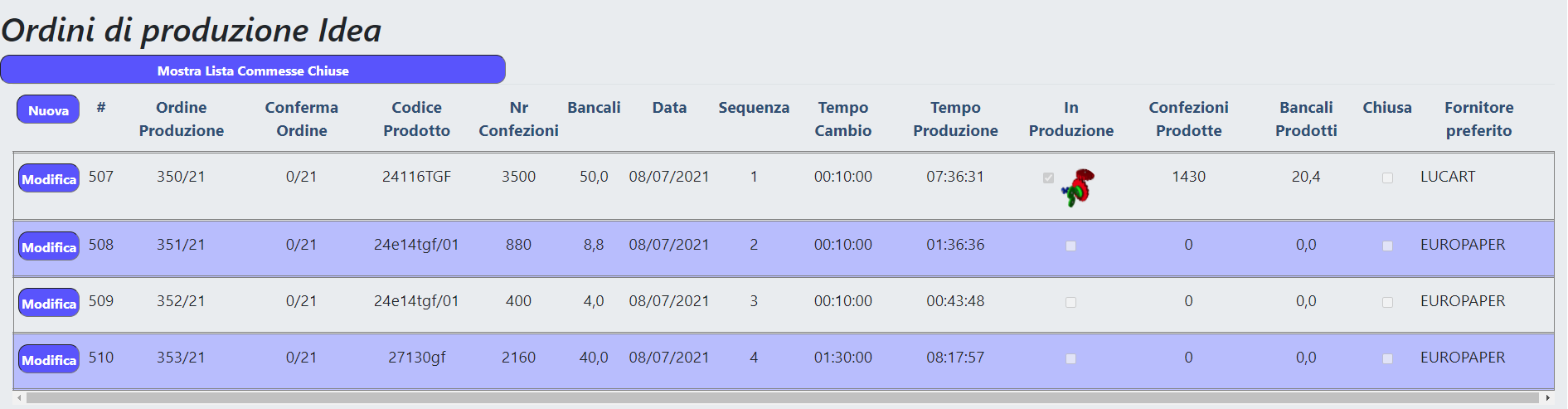

Planning

Allow the planning of production orders, sending recipes and quantities to be produced to the lines, following their progress in real time.

─ 5

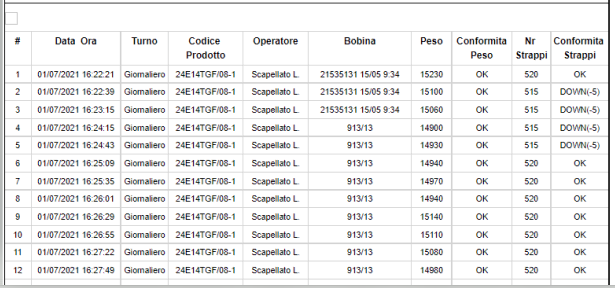

Track

Check that the production parameters are within the limits.

─ 6

Display

Control panels that indicate the status and progression of orders